Helical Gears

Higher Load Carrying Capacity Over Spur Gears

Helical Gear

Size Range and Capability for Helical Gears

Maximum Pitch Diameter – 36”

Diametral Pitch – 3.0 – 48

Face Width – 13.0

Unground Tooth – AGMA Q9

Ground Tooth – AGMA Q13

Helical gear teeth in mesh

Spur Gears

The Simplest Form of Parallel Axis Gears

While widely known for our bevel gear products, Arrow is also a leading supplier of spur gears.

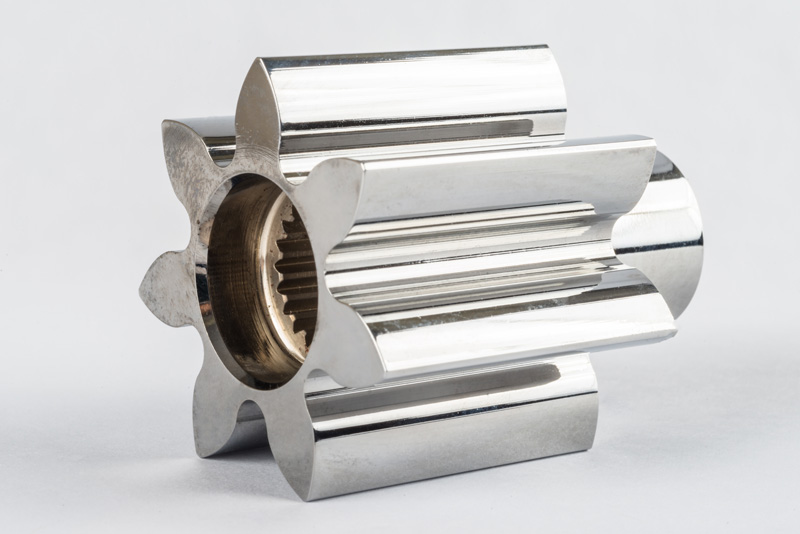

Pump Gears

Pump gears are similar to spur gears in their geometry. However, pump gears are not used to transmit power between shafts. Instead, they are used for the positive displacement of fluid in pumping applications - most commonly for fuel systems. The benefit of using pump gears in this application over other methods is the precise volume of fluid that is displaced during each revolution.

Pump Gear

Pump Gear

Size Range and Capability for Spur Gears

Maximum Pitch Diameter – 36”

Diametral Pitch – 3.0 – 48

Face Width – 13.0

Unground Tooth – AGMA Q9

Ground Tooth – AGMA Q13

This animation shows two involute gears rotating in mesh, with the left driving the right. The blue arrows show the contact forces between the two gears.

Fig.1 - This animation shows the basic principle of how an involute profile is formed.

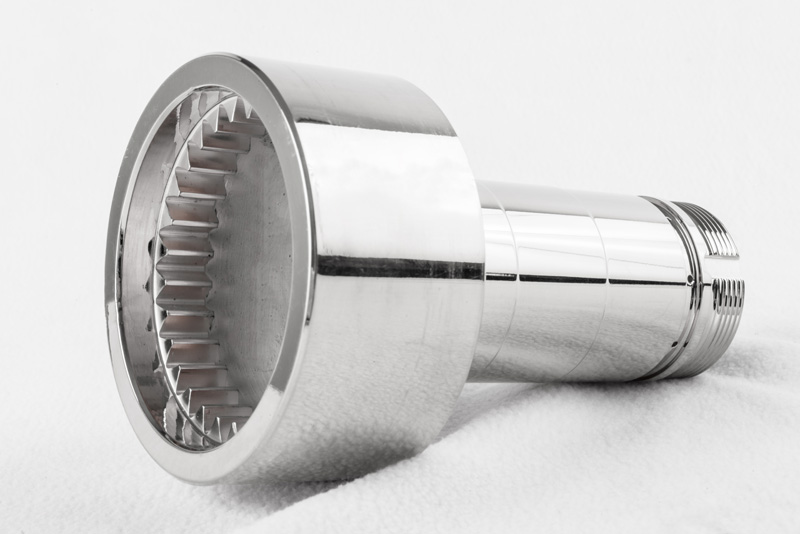

Splines

For Positive Engagement of Mating Parts

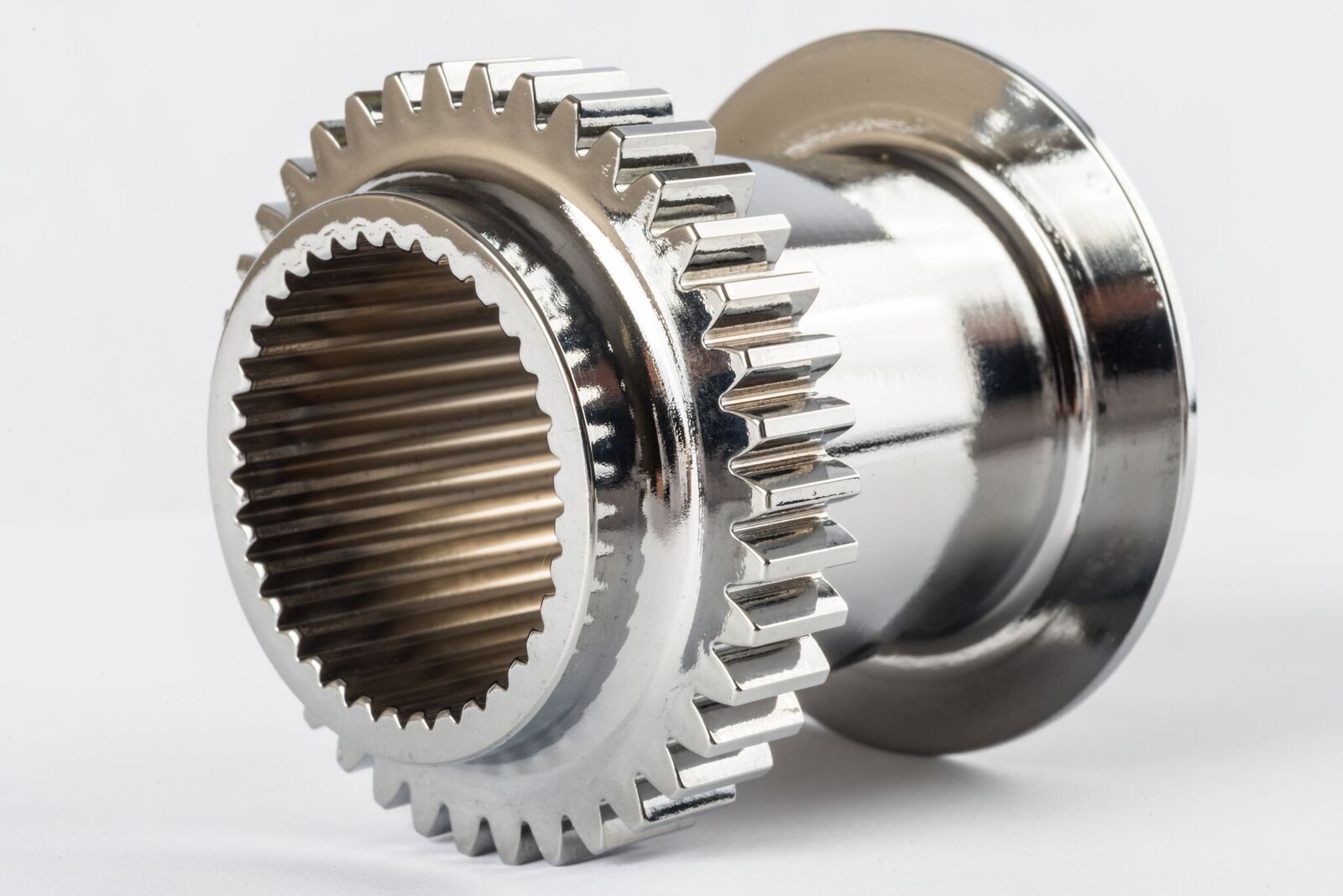

Spline Gear

Size Range and Capability for Spline Gears

Maximum Pitch Diameter – 32”

Diametral Pitch – 4/8 - 80/160

Face Width – 13.0

Unground Tooth – AGMA Q9

Ground Tooth – AGMA Q13

External spline on the shaft of a bevel gear

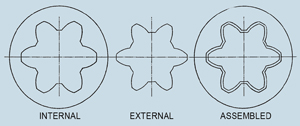

Arrow produces three types of splines which are detailed as follows.

Fig. 1 - Involute Splines

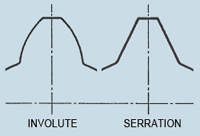

Fig. 2 - Comparison of Involute

and Straight Sided Serration Splines

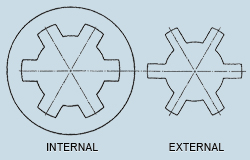

Fig. 3 - Straight Sided Splines

- Internal and External

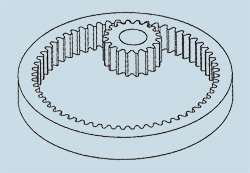

Internal Spur Gears

For Compact, High Load Carrying Capacity

Internal Spur Gear

Size Range and Capability for Internal Spur Gears

Maximum Pitch Diameter – 32”

Diametral Pitch – 3.6 – 48

Face Width – 8.0

Unground Tooth – AGMA Q9

Ground Tooth – AGMA Q13

Illustration of Internal Spur Gear

with mating external spur gear